WENZHOU DABA MACHINERY CO., LTD.

As a professional manufacturer of all kinds of label machines, was established more than ten years ago. Our company consists of Technical Development Department, Manufacturing Department, Domestic and International Sales Department and After-Sales Service Department.

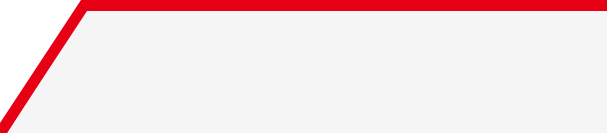

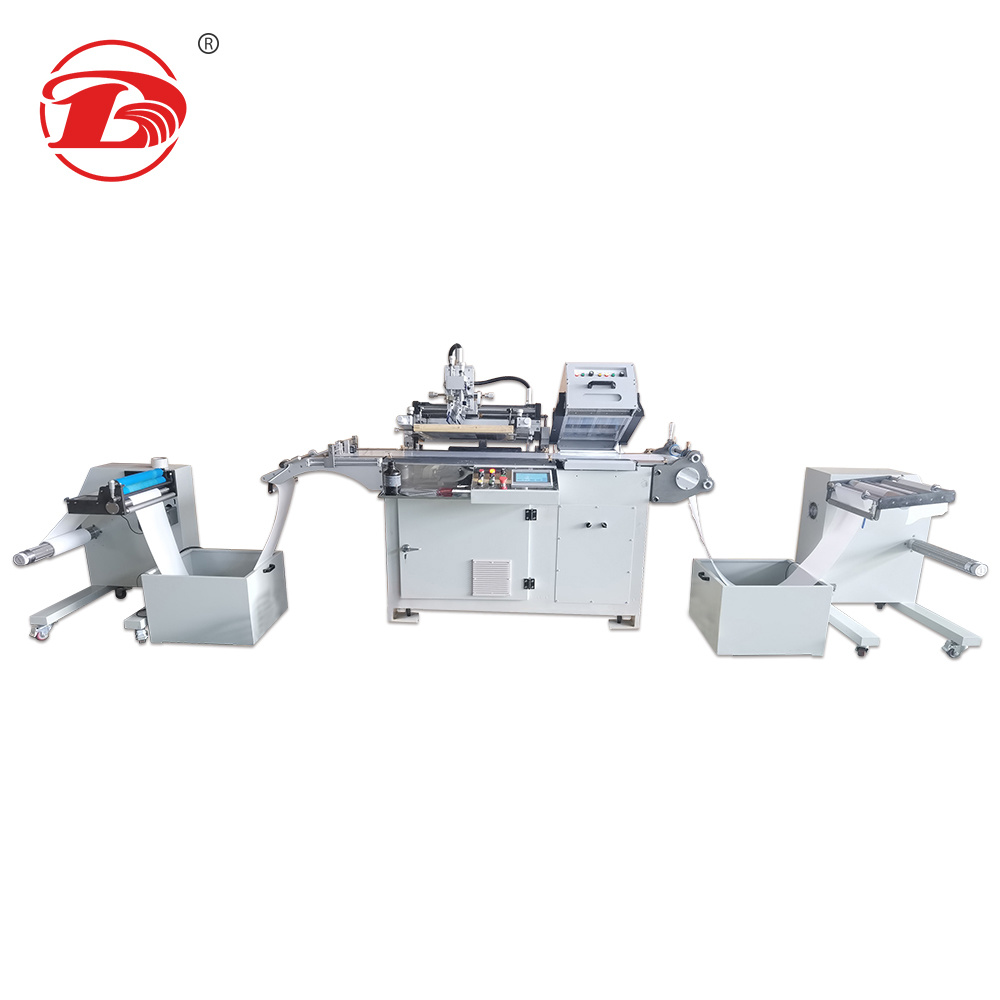

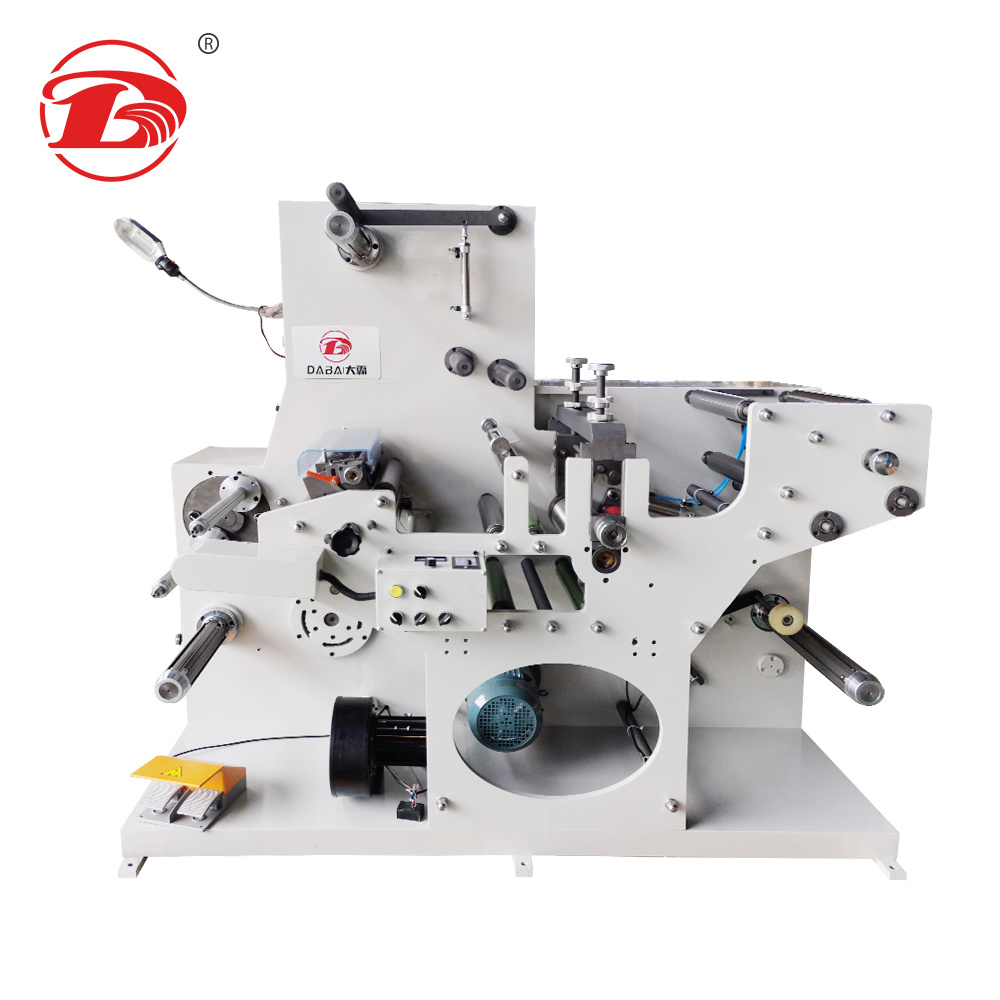

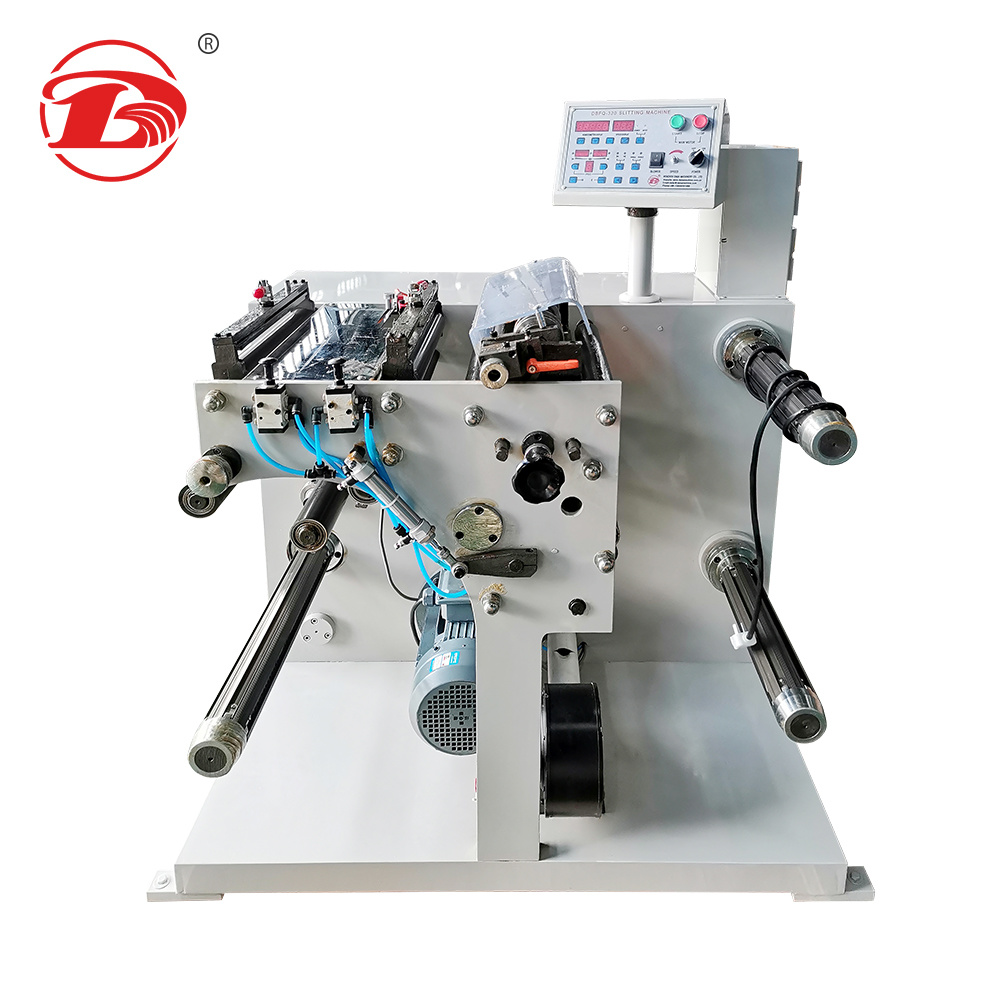

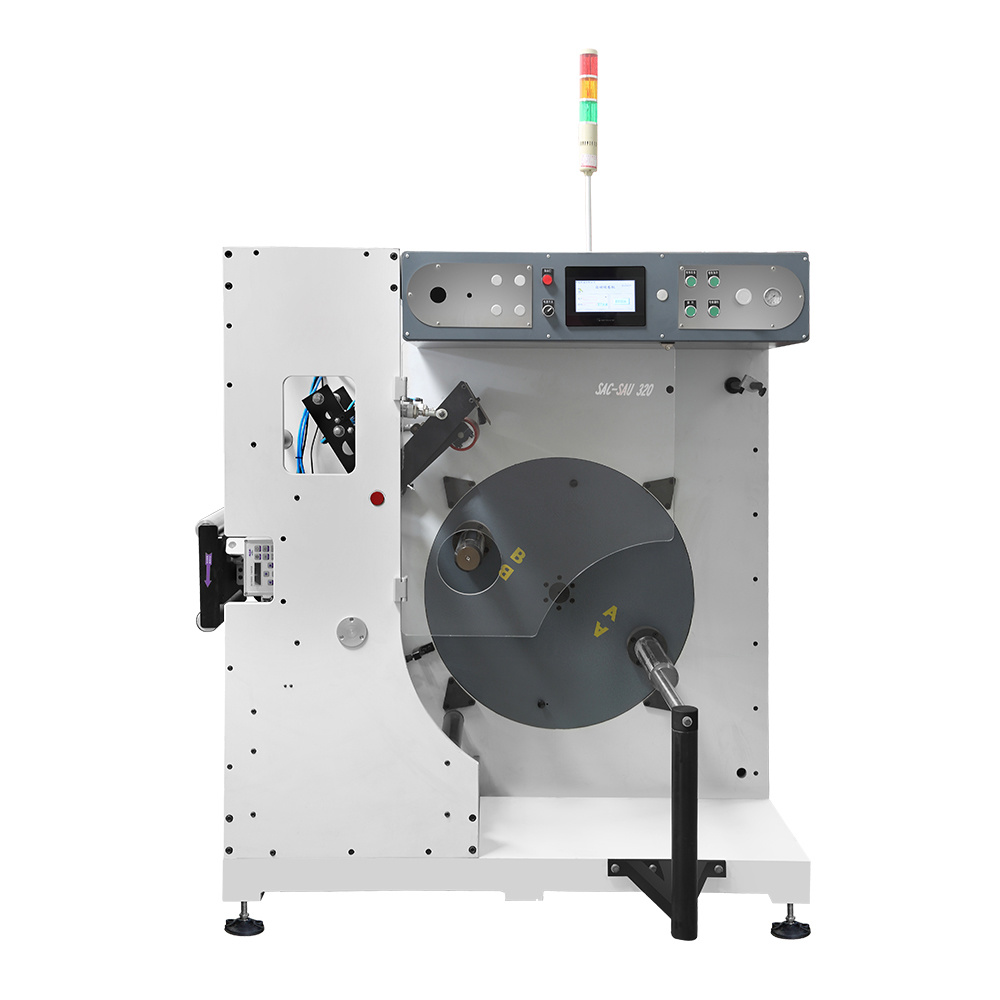

Our main products include: Self adhesive label production line (adhesive label flexo printing machine, label die cutting machine, label slitting machine), laminating and coating machine ...

DABA

ADVANTAGES

Wenzhou Daba Machinery Co., Ltd

For over 20 years, our company has been a leader in Chinese label machinery area. we have got ISO9001 Quality Management System Certificate and some products have got CE Certificate.

OUR

MARKET

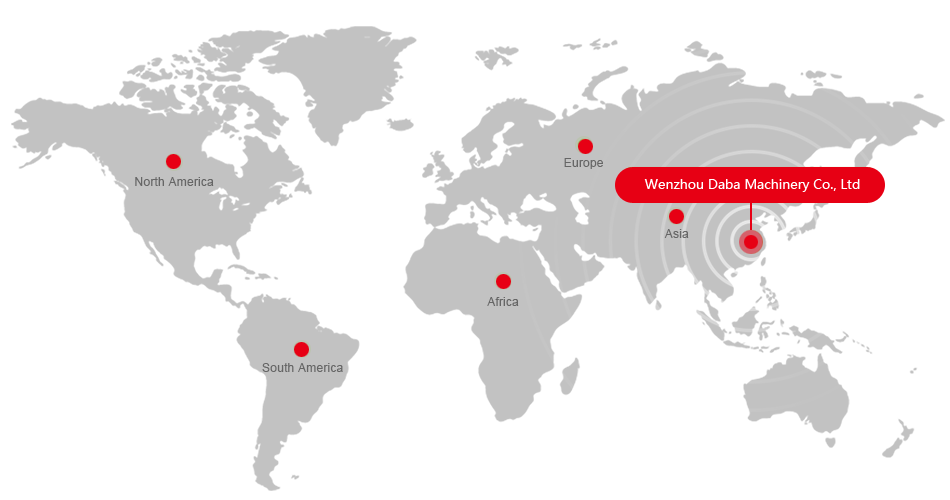

Global sales and service organisations

Our products sell well in Asia (such as India, Thailand, Vietnam, Indonesia, Malaysia, Sri Lanka), the Middle East (Iran, Pakistan), Europe (Russia, Bulgaria, Croatia, Rumania, Spain, Italy), Africa (Nigeria, Guinea, Congo), North America and South America.

Learn the latest information of the company

# Introduction In the world of manufacturing and processing machinery, the industry of plate making and printing machines stands out for its precision and innovation. One such standout in the industry is Zonten, a leading manufacturer of flexo printing machines. In this article, we will delve into the art of precision printing with Zonten flexo printing machines and explore the insights behind the

2024-04-25

Label flexo printing machines are essential equipment in the manufacturing and processing machinery industry, specifically in the field of flexographic printing. These machines are used to print high-quality labels on various types of materials, such as paper, plastic, and film. Here are some key points to consider when it comes to label flexo printing machines: 1. Technology: Label flexo printing

2024-04-24

Manufacturing Processing Machinery - Plate Making and Printing Machinery - Flexo Printing Machines In the fast-paced world of manufacturing, precision and efficiency are key factors in staying ahead of the competition. One industry that relies heavily on precision printing is the flexo printing sector. Flexo printing machines are the workhorses of the printing industry, providing high-quality prin

2024-04-23

Label flexo printing machines are essential equipment in the manufacturing and processing machinery industry, specifically within the realm of flexographic printing. These machines play a crucial role in producing high-quality labels for various products, ranging from packaging materials to promotional items. One of the key advantages of label flexo printing machines is their ability to print on

2024-04-22